Article

We commit to sustainability – join us!

Article by Jari Auvinen, Sales Manager

The role of accurate flow measurement in industrial sustainability

Efficiency and sustainability have become important concerns in industrial operations. With the global push towards reducing environmental impact and optimizing resource usage, precise flow measurement and monitoring have emerged as crucial components in achieving these goals.

Understanding Flow Measurement

Flow measurement refers to the quantification of liquids such as water and oils or various gases such as air moving through pipelines or systems in an industrial application. Accurate measurement ensures that the right amount of media is delivered at the right time and place within industrial processes.

Contribution to Sustainability

1. Resource Optimization

Precise flow measurement helps in optimizing resource usage. By accurately defining and configurating the amount of flowing media passing through systems, industries can minimize waste and excess consumption. This optimization, in turn, conserves resources and reduces overall environmental impact.

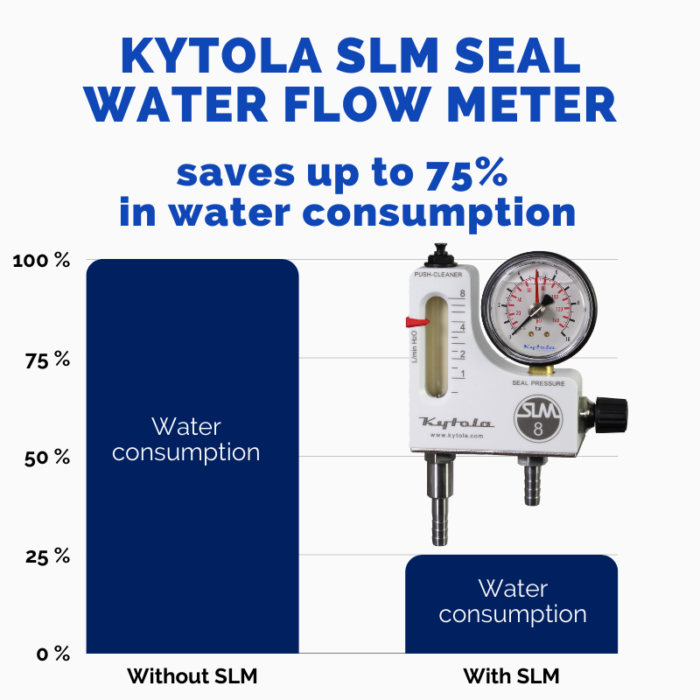

Kytola SLM seal water flow meter helps you save up to 80% water

2. Energy Efficiency

Monitoring flow rates helps identify inefficiencies in systems. By pinpointing areas where there is either excess or insufficient flow, adjustments can be made to optimize energy consumption by using adequate but not excess amount of flowing media. This optimization directly contributes to reducing carbon footprints and operational costs.

Kytola Smart variable area flow meters with mA output to control room enable both visual monitoring on site and a signal to control room.

3. Emissions Reduction

Accurate flow measurement plays a crucial role in emission control. Industries can accurately monitor and regulate the release of gases and fluids, ensuring compliance with environmental regulations. Minimizing emissions through precise measurement aids in maintaining environmental sustainability.

4. Process Improvement

Detailed flow monitoring provides insights into the performance of industrial processes. Analyzing this data allows for continual process improvement, leading to enhanced efficiency, reduced waste, and better utilization of resources and secured processes. For example crucial bearing failures of process machinery are easily avoided with precise oil flow lubrication monitoring and control.

Kytola oval gear flow meters for Kytola Oval Flow system always show the correct flow rate regardless of temperature or viscosity changes.

Challenges and Future Prospects

While advancements in flow measurement technology have improved accuracy, challenges persist. Calibration, maintenance, and compatibility with varying substances are ongoing concerns that we at Kytola continuously work on to fine tune in our products.

However, ongoing research and development promise even greater accuracy and efficiency. We suggest to use flow measurement devices that have a proven track record and that are approved by the major companies in their field.

Adding Kytola Smart products to complete your flow measurement calls for increased data and secured processes.

Conclusion

Accurate flow measurement and monitoring are indispensable in the pursuit of sustainability within industrial applications. The precision offered by these technologies not only optimizes resource usage and energy efficiency but also aids in reducing emissions and improving overall operational effectiveness.

As industries continue to prioritize sustainability, the role of accurate flow measurement will remain pivotal, driving progress towards a more environmentally conscious and efficient future.