Part 2.

Control your processes better by saving water and labor time

Part 2.

By Martin Valois

In the second part of this blog series, we dive into the world of wet leg purging. Accurate level measurements are paramount for operational efficiency in industrial processes. One method that plays a crucial role in achieving precision is wet leg purging, specifically designed for DP (Differential Pressure) level transmitters.

This method becomes essential in applications where the process fluid has the potential to clog or contaminate the impulse lines or sensing lines leading to the transmitter, potentially jeopardizing the accuracy of level measurements.

Wet Leg Purging involves the strategic use of continuous flow of clean water to ensure a clear and uncontaminated path for the pressure transmission between the process vessel and the DP transmitter. This method not only safeguards against clogging and contamination but also guarantees that the level measurements remain accurate and reliable.

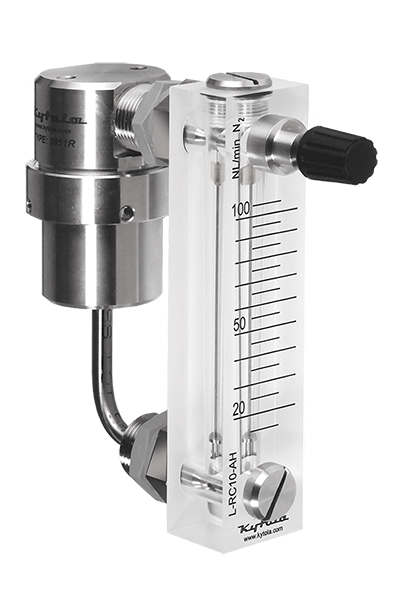

The Role of Kytola’s Constant Flow Regulators:

At the heart of wet leg purging lies the constant flow regulator, a critical component that significantly contributes to the accuracy and reliability of DP level transmitters. The constant flow regulator ensures a consistent flow of purging fluid, maintaining an optimal environment for pressure transmission. By doing so, it safeguards against potential disruptions caused by clogs or contaminants in the system.

One of the key advantages of incorporating a constant flow regulator in wet leg purging is its ability to automate the purging process. This eliminates the need for frequent manual adjustments or interventions, reducing the overall maintenance requirements. As a result, the transmitter’s performance remains consistently reliable, and operational downtime is minimized.

Reduced Maintenance, Increased Reliability:

The automation facilitated by the constant flow regulator not only streamlines the wet leg purging process but also contributes to a decrease in maintenance demands. This reduction in manual interventions translates to lower operational costs and increased overall reliability of the DP level transmitter in industrial applications. It’s a win-win situation that empowers industries to focus on their core processes without compromising on measurement precision.

Controlled water purging of DP wet legs is undeniably a cornerstone in ensuring accurate and reliable level measurements in industrial settings. The strategic use of Kytola Instruments’ constant flow regulator in this process not only automates the purging operation but also minimizes the need for manual adjustments, reducing maintenance requirements, and enhancing overall reliability.