The answer is actually very simple: customers want constant high quality, accuracy and reliability.

Kytola’s customer orientated and highly skilled staff is always ready to listen customers’ needs and eagerly responding to those while prioritizing long lasting, high quality solutions.

There are numerous producers of flow meters which manufacturing methods and standards are not as high as Kytola’s and consequently the accuracy and constant quality suffers from it. These flow meters might be a lot cheaper to produce but typically have many disadvantages.

If you would put such a flow meter under a microscope, you would see that the inner tube where the float is moving up and down is very rough. A small bit of contamination or moist will stick to the wall causing the float not to move freely.

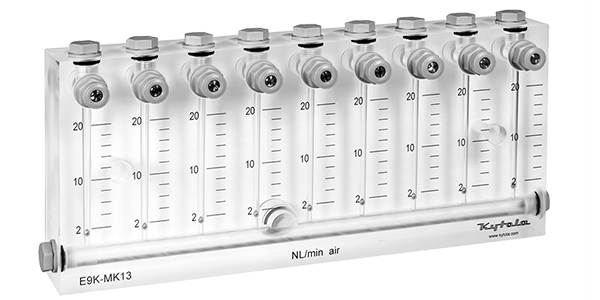

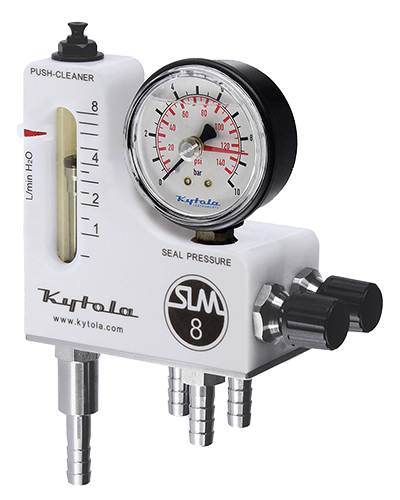

Kytola flow meters are produced with state-of-the-art CNC machines which provide their impeccable quality compared to several products on the market. CNC machines are high precision tools that are computer controlled and make the manufacturing process highly efficient. Materials used for production go through a strict quality control system. The plastic gets a special treatment to prevent expansion or shrinking due to temperature and pressure changes while in use.