Part 1.

Control your processes better by saving water and labor time

Part 1.

By Martin Valois

By combining precise flow control with water conservation and automation, constant flow regulators offer a comprehensive solution to improve process control, save water resources, and reduce labor time.

In this three-part blog series, we will delve into the multifaceted world of constant flow regulators, exploring their significance in different industrial contexts.

Certain industrial equipment, such as shaft seals in pumps, and pressure transmitters, have optimal water purge flow rates for safe and efficient operation. Deviations from these ranges can lead to equipment malfunction, damage or inaccuracies. Constant flow regulators protect such equipment by ensuring it operates within the designated flow parameters.

Constant flow regulators maintain a consistent and controlled flow rate of water, regardless of fluctuations in pressure. This precision ensures that only the required amount of water is used for a particular application, preventing overuse.

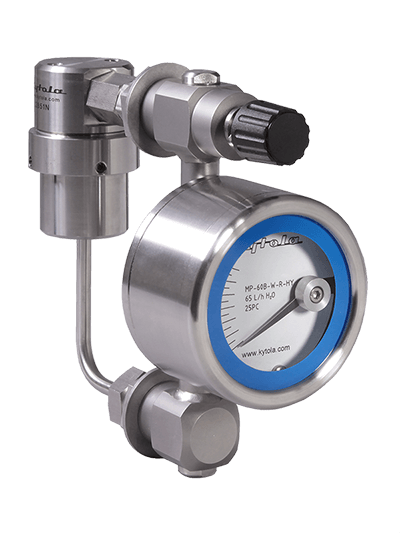

Constant flow regulators automate the control of water flow rates, eliminating the need for manual adjustments or interventions. Operators no longer need to continuously monitor and adjust valves on Kytola models L, VL, MP and SLM to maintain desired flow rates and are free for other tasks.

Constant flow regulators find applications in various industries and systems where maintaining a specific flow rate is critical.

Example:

Seal Water

Effective seal water flow rate control is crucial for preventing seal failures, minimizing downtime, and ensuring the safety and efficiency of industrial processes. Variations of pressure will affect the flow rate within a seal water system. To maintain a consistent flow rate, Kytola constant flow regulator models 2851 or 2914, can be combined with our SLM and or model VL for higher flowrate.

By implementing the right control measures and monitoring systems, you can avoid alarms and maintain optimal seal water flow rates.

As we conclude this first part of our journey into the world of constant flow regulators, it is clear that, by merging precise flow control with water conservation and automation, constant flow regulators offer a comprehensive solution that not only enhances process control but also promotes sustainability and efficiency.

In the following parts of this series, we will continue to explore the real-world applications and concrete examples of how constant flow regulators are important tools in various industrial contexts. Stay tuned for the next chapters.