Kytola oil flow monitoring products are widely used in rolling mills. They have proven reliable and failure-free operation in hot, cold and finishing rolling lines. Kytola flow meters are also used in oil lubrication for large gearboxes in metal mills.

Rolling mill machine manufacturers value highly this kind of oil lubrication flow monitoring arrangements. We have delivered customized combinations of flow monitoring devices and measuring stations worldwide. We have been extraordinary successful with supplying oil lubrication flow monitoring systems to metal rolling mills producing different steel grades and aluminium products such as alloy steel, stainless steel, tool steel and TMT bars.

Oil circulation unit suppliers see huge advantages in integrating different types of flow meters to their systems. Advanced flow measurement with Oval D2 measuring stations or the KLD touchscreen display complete the set up.

Most used Kytola products for this kind of application are:

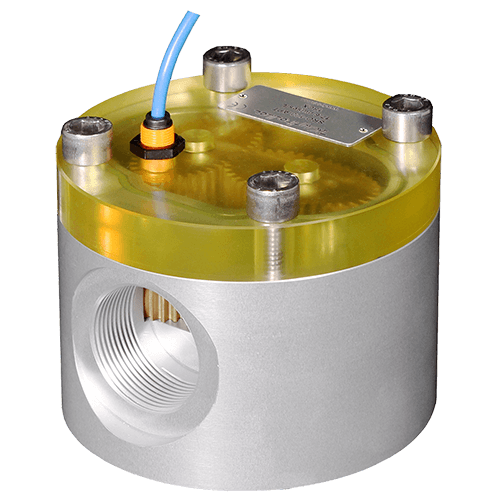

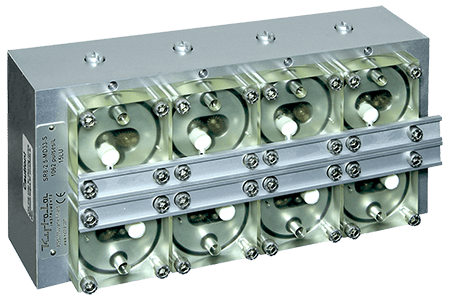

- Kytola Oval Flow panels with Oval D2 measuring station and SR oval gear flow meters

- KLD Smart touchscreen display with SR oval gear flow meter blocks

- VExA multitube oil flow meters