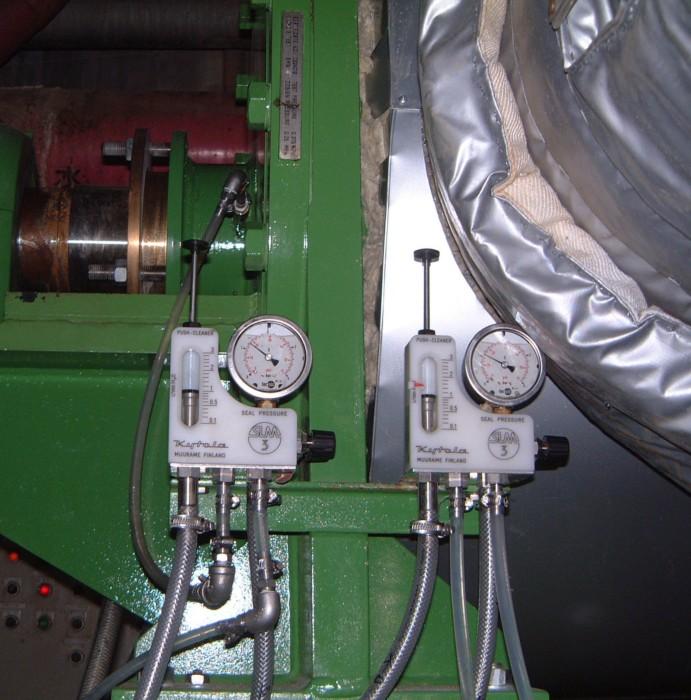

Tiivisteveden valvonta ja hallinta

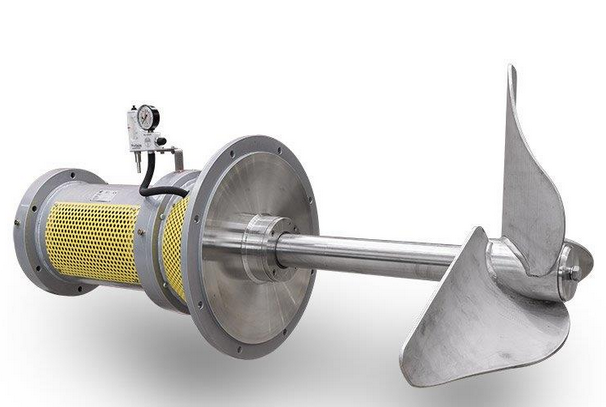

Useimmat pumput, sekoittimet, sihdit ja jauhimet sekä muut pyörivillä akselitiivisteillä varustetut laitteet vaativat keskeytymättömän tiivisteveden virtauksen tiivisteen asianmukaisen toiminnan varmistamiseksi.

Tiivisteveden tehtävänä on jäähdyttää ja voidella tiivistettä sekä estää prosessinesteen pääsy tiivistepesään.

Tiivisteveden virtauksen ja paineen asianmukaisella valvonnalla voidaan myös arvioida tiivisteen kuntoa.