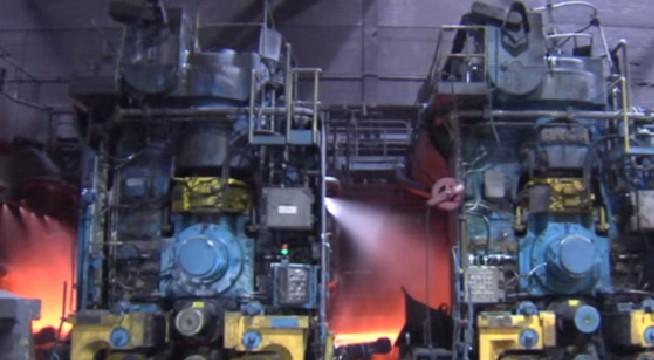

Lubrication oil flow monitoring in rolling mills

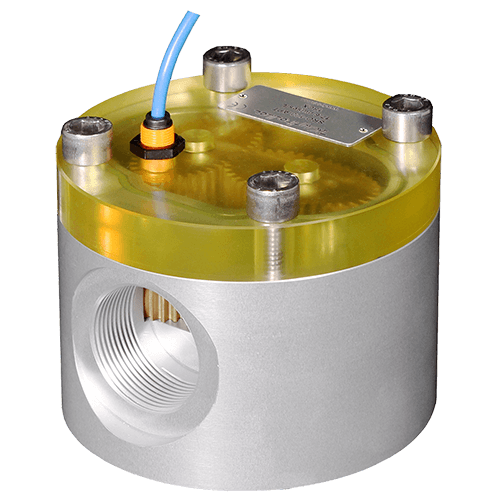

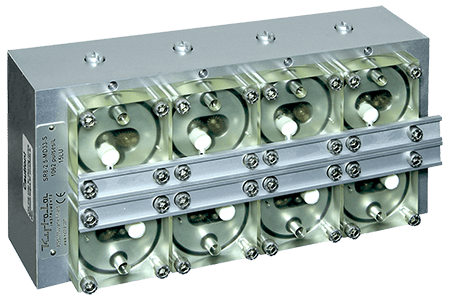

Proper bearing and gear lubrication is essential for reliable operation of all machinery. The main purpose of oil circulation lubrication is to lubricate and reduce friction, transfer heat and contaminants and to protect the target from corrosion.

Kytola oil flow monitoring products are widely used in rolling mills. They have proven reliable and failure-free operation in hot, cold and finishing rolling lines. Kytola flow meters are also used in oil lubrication for large gearboxes in metal mills.